- Description

- Material Capabilities

- Technical Specs

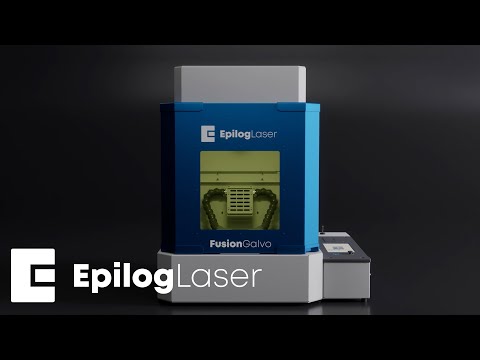

The Fusion Galvo G100 is our high-speed fiber laser marking system engineered for precise and efficient marking and engraving of metals, ceramics and engineered plastics. This popular system includes dual-lens capabilities, the IRIS™ Camera System that allows for easy and accurate artwork placement, an automated mechanical door, user-friendly interface, and so much more.

If you’re looking to serialize or mark metal or engineered plastic parts or components, this is the machine for you.

Wattage Options

The Fusion Galvo G100 is available in the following wattage options: 30-watt MOPA, 60-watt MOPA, or 100-watt MOPA fiber laser configurations.

Do I need the Exhaust and/or Filtration System Accessory?

All lasers need extraction of particulates generated during the marking engraving process; either exhaust to the outside or use an internal filtration unit to clean the air of dust and debris, so you can either use our recommended options, or source one on your own. The Fusion Galvo G100 requires an exhaust fan that is rated at a minimum of 450 CFM for external exhaust. Factors such as length and type of tubing from the Epilog laser to the exhaust fan and from the exhaust fan to the outside of the building can produce significant losses on the true amount of air that is drawn from your machine. The portable exhaust unit will require metal ducting leading to and from the laser system and exhaust fan. It attaches to a 4" exhaust port on the back of the laser system.

Recommended dust collector: 1.5HP DC3 Portable Dust Collector Motor Blower (no bag or hose) at Penn State Industries

Recommended filter unit: Filtrabox Compact X Fume Extractor | Filtrabox.com

Shipping

All machinery is shipped in 1-2 weeks with a lift gate.

Training

Online training is included with the system through Epilog’s extensive Support Center. Here you can select your machine and walk through a variety of video tutorials that cover getting started, usage and operation, and service and repair. For in-person training, please contact your local rep to inquire about or purchase additional training packages.

Is additional cooling required?

No, additional cooling is required. As with all Epilog laser systems, we use state-of-the-art laser sources that do not require water cooling. The G100 laser system incorporates an air-cooled ytterbium fiber laser.

How do I get support?

Epilog machines come with a 2-year warranty that covers all parts of the system, including the laser source. If you have an issue with your system, you'll contact our Technical Support department, and they will help to diagnose the problem and ship the parts out to you. The machines are designed so they can be repaired easily by you, and the step-by-step video instructions in the resource center walk you through the replacement of common parts of the machine. Even after your warranty has expired, lifetime assistance is provided for the machines.

Where is the system manufactured?

Since 1988, Epilog has been designing, engineering, and supporting our machines from our global headquarters in Golden, CO.

Why should I work with my distributor instead of buying online?

If you need additional help purchasing a machine, there is no one more experienced with our equipment than our distributors. Many of our associates have been working with Epilog for 30+ years! Your local rep can assess your marking application needs, provide an in-person demonstration, and help you select the machine that’s going to meet your engraving and cutting demands. You can find your distributor by clicking here.

What if I can't purchase with a credit card?

If your credit limit isn’t compatible with the laser purchase price, your local rep can take a variety of payment options, including purchase orders. They can also assist with leasing resources. And don’t forget you can use Paypal to send funds directly from a bank account.

I have more questions!

Contact us at 303-277-1188 or sales@epiloglaser.com and we'll be happy to answer any questions you have. If you're not ready to buy today, fill out the form on our website and we'll send you a full product line brochure and free laser engraved and cut samples!

With the Fusion Galvo, mark a wide array of metals and engineered plastics.

| 17-4 PH stainless steel | 303 stainless | 4043 steel | 6061 Aluminum |

| ABS (white/black) | Aluminum, 6061 | Aluminum, yellow chromate | Bayer 2807 Makrolon polycarbonate |

| Bayers bayblend FR110 | Black/white ABS | Black/white polycarbonate | Brass |

| Brushed aluminum | Carbon nanotube | Ceramics, metal-plated | Clear coat anodized aluminum |

| Cobalt chrome steel | Colored delrin (black/brown) | Compacted powder iron with phosphate coating | Copper |

| DAP – Diallyl Phthalate | Delrin, colored (black/brown) | GE Plastics polycarbonate resin 121-R | Glass filled PEEK |

| Glass filled Teflon | Hard coat anodized aluminum | Inconel metals (various) | Machine tool steel |

| Magnesium | Metal-plated ceramics | Molybdenum | Nickel plated 1215 mild steel |

| Nickel plated brass | Nickel plated gold | Nickel plated Kovar | Nickel plated steel |

| Nylon | PEEK, white | Polybutylene Terephthalate | Polycarbonate (black/white) |

| Polycarbonate resin 121-R, GE Plastics | Polycarbonate, Bayer 2807 Makrolon | Polysulphone | Rynite PET |

| Santoprene | Silicon carbide | Silicon steel | Silicone wafers |

| Stainless steel 303 | Stainless steel 17-4 PH | Steel 4043 | Steel, machine tool |

| Various inconel metals (nickel-chromium super alloys) | White PEEK | Yellow chromate aluminum | Zinc plated mild steel |

| And Many More! | |||

| Do you have a material you would like us to test? Our Applications Team would be happy to assist you. | |||

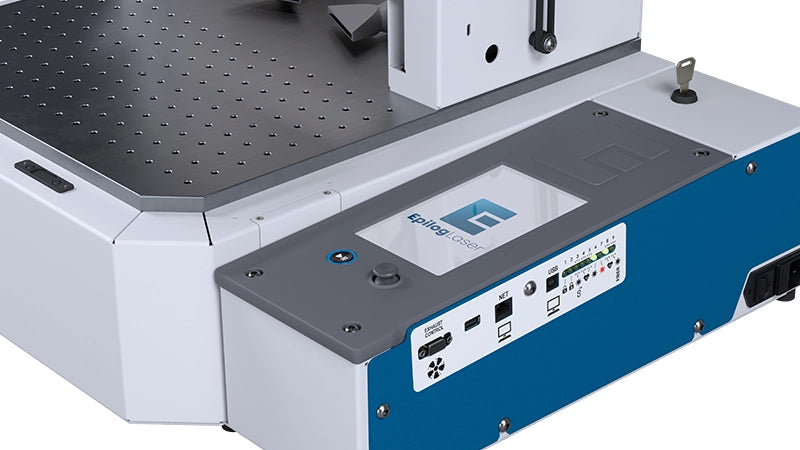

Laser Machine: |

FUSION GALVOMetal Marking Machine

|

Work Area: |

F163: 4" x 4" (101 x 101 mm) F254: 6" x 6" (152 x 152 mm) |

Material Thickness: |

F163: 10" (254 mm) F254: 6" (152 mm) |

Laser Source: |

Fiber, air-cooled, 1064nm |

Laser Source Wattages: |

30 watt MOPA, 60 watt MOPA, or 100 watt MOPA fiber configurations |

IRIS™ Camera System: |

2 overhead |

Software Compatibility: |

Works with most Windows-based CAD and design software |

Wireless Connectivity: |

Included |

Included Lenses: |

F163 and F254 lens |

Resolution: |

Fully-flexible & user-controlled from 75 – 1200 dpi |

Print Driver & Software: |

Laser Dashboard™, Epilog Job Manager™ |

Internal Memory: |

Store multiple files up to 1 GB. Engrave any file size. |

Super-Silent Cooling Fans: |

Included |

Job Trace: |

Included |

Auto Focus: |

Included |

Touch Screen: |

Included |

Max Table Weight: |

100 lbs (46 kg) |

Size (W x D x H): |

28" x 23" x 31" (door closed) 37" height (door open) 711mm x 584mm x 787mm / 940mm |

Weight: |

131 lbs (59.5 kg) |

Electrical: |

Auto-switching 100-120 volts, Amp draw-MAX: 13A Auto-switching 220-240 volts, Amp draw-MAX: 6.5A 50 or 60 Hz, single phase |

Ventilation: |

450-650 CFM (764-1104 m3/hr) |

Class |

Class 2 Laser Product – 1 mW cW MAXIMUM 600-700nm |

Product Details

The Fusion Galvo G100 is our high-speed fiber laser marking system engineered for precise and efficient marking and engraving of metals, ceramics and engineered plastics. This popular system includes dual-lens capabilities, the IRIS™ Camera System that allows for easy and accurate artwork placement, an automated mechanical door, user-friendly interface, and so much more.

If you’re looking to serialize or mark metal or engineered plastic parts or components, this is the machine for you.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.